Dedicated to vehicle interiors, our greatest assets can be found on the production floor. Together, our tenured operations and supply chain teams collaborate to achieve on-time delivery of high-quality interior products with every shipment. Manufacturing engineering teams invest in advanced technologies and process optimization focused on sustainable, long-term growth, while tooling, maintenance, and technical trades follow preventative protocols to maintain current equipment.

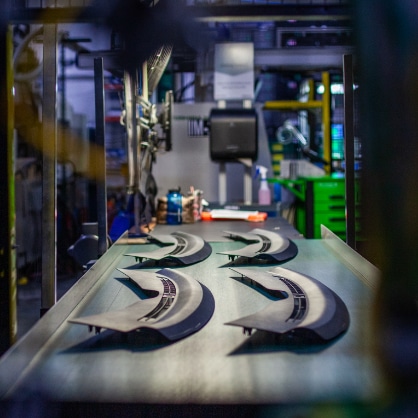

Injection Molding

Injection molding technologies are at the core of the Kendrick operation. Our diverse molding capabilities are led by a highly experienced process engineering and tooling team focused on best-in-class quality, delivery, and cost-competitiveness.

- 50+ injection molding machines, 85 – 1200 tons

- Broad process expertise including, mold in color, film insert molding, applique decorative trim

- Robotic part unload, label placement, and dimensional

accuracy

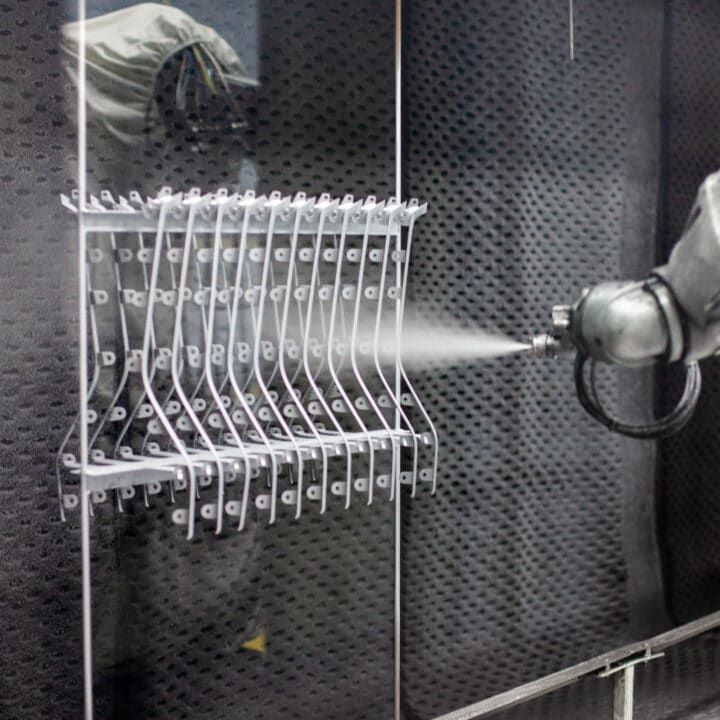

Painting Technologies

With an increasing number of interior options offered by auto manufacturers, Kendrick is continuously innovating to offer advanced solutions. Our dedicated in-house paint engineers utilize proprietary processes to produce customer-specific designs, colors, and finishes:

- Fully automated robotic paint lines and RTO system

- Single and double-sided painting solutions

- Haptic, solvent, and water-based paint capable

- 9 robots cleaning and painting capable

Assembly & Sequencing

Kendrick utilizes over 150 flexible workstations to accommodate virtually every assembly and component joining techniques found within interior trim. Customers that have part sequencing requirements are served through In-Line Vehicle Sequencing (ILVS), a solution that is integrated directly into our manufacturing execution system.

Interested In Working With Kendrick?

Kendrick Plastics is a growing company focused on world class design and manufacturing. We are always looking for like-minded customers, vendors and partners who share our vision for enhanced vehicle interiors.